The FA186G Absorbent Cotton Sliver line consists of an opening machine, a cotton feeding box, a carding machine and one or more independently controlled coilers. Can be equipped with multiple carding machines at the same time. Usage: used in the production of combing cotton swabs, cotton balls, medical cotton, and cosmetic cotton Features: The absorbent cotton is opened by the opening machine and put into the cotton box. The cotton box is evenly fed into the carding machine. It can be equipped with 4 coilers, and the minimum cotton sliver can be carded out is 1.0 g/m.

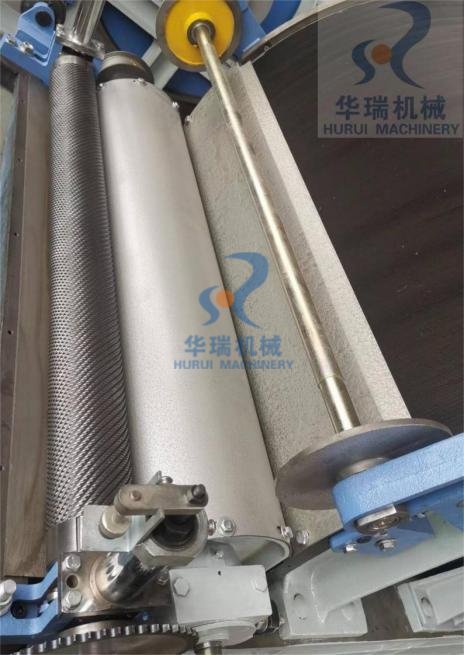

The Φ100mm diamond shaped cotton feeding roller is used to feed cotton more evenly and smoothly.

It is equipped with the advanced FT-037 automatic leveler system, which improves the uniformity of cotton feeding, reduces the error of cotton strip weight, and significantly improves the cotton strip weight CV%.

Using the air flow striping method, the air pressure can be adjusted according to the air flow conditions.

At the same time, it can synchronically output 1-4 cotton strips. The number and weight of cotton strips can be adjusted as required.

(company's patented product, patent number: ZL201620895633.8).

1. The FA186G Absorbent Cotton Sliverline consists of an opening machine, a cotton feeding box, a carding machine and one or more independently controlled coilers. Can be equipped with multiple carding machines at the same time. Usage: used in the production of combing cotton swabs, cotton balls, medical cotton, and cosmetic cotton Features: The absorbent cotton is opened by the opening machine and put into the cotton box. The cotton box is evenly fed into the carding machine. It can be equipped with 4 coilers, and the minimum cotton sliver can be carded out is 1.0 g/m.

2.The feeding motor operates independently, is controlled by a frequency converter, and uses an RV reducer.

3.The independent feeding motor and doffer motor are controlled by frequency converters, and the speed can be adjusted according to needs.

4. The electrical appliances are concentrated in the cotton feeding box to reduce the space occupied. The operation display screen is at the front of the carding machine, making it easy to operate.

5. The cylinder card clothing, doffer card clothing and flat card clothing of this machine are all made of GERON high-quality card clothing.

6. The large brush is made of DuPont material and has a long service life.

7. The sliver can of the coiler adopts a large barrel with a diameter of 600mm and a height of 900mm, which has a large capacity.

8.The feeding roller adopts a diamond-shaped roller with a diameter of 100mm, and the cotton is fed more evenly.

Production ration | 1.0 ~ 15.0 g/m |

Yield | up to 20 kg/h |

Working width | 1000mm |

Working speed of cotton chemical fiber take-in roller | 1070 rpm (cotton), 980 rpm (chemical fiber) |

Cylinder working diameter | φ 1289 mm |

Doffer working diameter | φ 706 mm |

Doffer working speed | 21.3~38.2 rpm |

Cotton fiber cover plate speed | 177 214 266 mm/min, 81 98 122 mm/min |

Coiler size | φ 600× 900 mm |

Wind pressure | 500~- 600 Pa |

Main motor | 3.3 kW |

Doffer driving motor | 1.5 kW (variable frequency) |

Floor area (long × Width) | 3809 × 2092 mm |

Total weight | about 5500kg |